dos screw

progressive cavity dispenser

progressive cavity dispenser

progressive cavity dispenser

endless dispensing power by dosmatix.

The dos screw progressive cavity dispenser complements the dosmatix dispenser portfolio with another innovative solution for precise, pulsation-free and continuous dispensing. This dispenser enables the application of very small, precise quantities starting from <1 µl, as well as continuous, uninterrupted bead dispensing at a speed of up to 600 ml/min. The result: precise, consistent, and material-friendly dispensing.

Thanks to its robust design, the dos screw is particularly suitable for applications with highly viscous, filled and thermally conductive materials.

precise, robust and multifunctional.

any questions about the product? contact us:

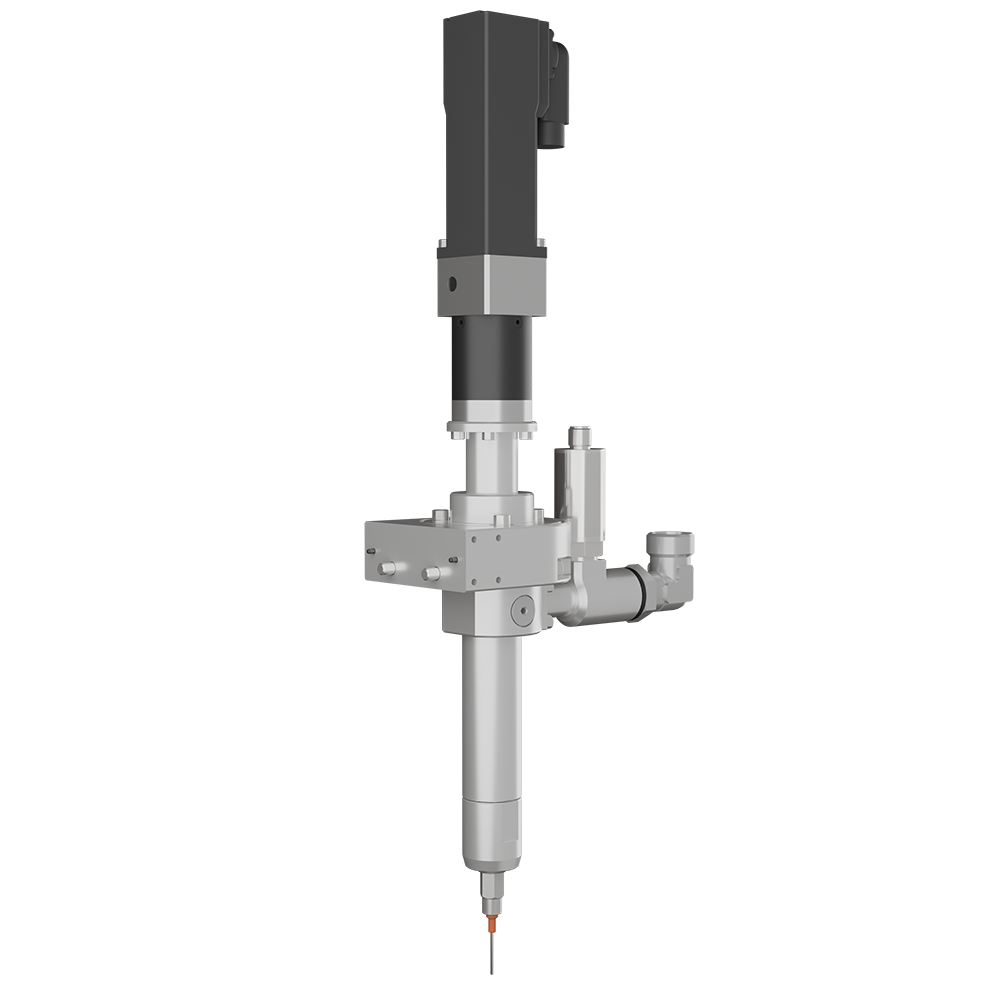

Flexible inlet with pressure sensor

Flow-optimized material guidance

Precise progressive cavity

Flexible dispensing outlet

Flexible inlet with pressure sensor (1)

The adjustable inlet allows flexible integration in different directions, ideal for adapting to complete systems. The integrated pressure sensor monitors the inlet pressure of the material and thus ensures precise pre-pressure.

Flow-optimized material guidance (2)

The flow-optimized material guidance in the housing of the stator to rotor ensures maximum performance and optimum dispensing speed.

Precise progressive cavity (3)

The simple control of the dispenser in both directions enables even and continuous material application. This ensures clean dispensing results with controlled tearoff without dripping.

Flexible dispensing outlet (4)

Thanks to the LuerLock connection with union nut on the outlet, various dispensing needles can be easily connected. This makes the dos screw ideal for a wide range of applications.

Other connections, such as threads, are also possible by simply replacing the connection piece.

| Variant 1C | XS | S | M | L | XL |

| Quantity per rotation | XS 3 µl or 10 µl or 50 µl | S 0.14 ml or 0.53 ml | M 0.35 ml | L 1.1 ml | XL 2 ml or 9.5 ml |

| max. dispensing speed* | XS 180 µl/min or 600 µl or 3000 µl | S 8.5 ml/min or 32 ml/min | M 21 ml/min | L 66 ml/min | XL 120 ml/min or 570 ml/min |

| min. dispensing quantity | XS < 1 µl or 1 µl or 5 µl | S 0.015 ml or 0.06 ml | M 0.04 ml | L 0.1 ml | XL 0.2 ml or 1 ml |

| Material viscosity | XS up to 1,000,000 mPa·s | S up to 1,000,000 mPa·s | M up to 1,000,000 mPa·s | L up to 1,000,000 mPa·s | XL up to 1.,000,000 mPa·s |

| Dimensions** (lxwxh) | XS 190 x 89 x 341 mm | S 182 x 89 x 353 mm | M 195 x 96 x 424 mm | L 200 x 96 x 452 mm | XL 200 x 96 x 471 mm |

| Weight aluminium*** | XS ca. 2.3 up to 2.9 kg | S ca. 2.3 up to 2.95 kg | M ca. 2.8 up to 3.5 kg | L ca. 3.9 kg | XL ca. 4.3 kg |

| Weight stainless steel*** | XS ca. 2.5 up to 3.3 kg | S ca. 2.6 up to 3.4 kg | M ca. 3.7 up to 4.4 kg | L ca. 5.1 kg | XL ca. 5.8 kg |

* 60 rotations/min

** without dispensing needle

*** incl. motor

Variant 2C: All 1C variants can be combined in different ways to form a 2C variant.

| Variant 1C | XS | S | M | L | XL |

| Quantity per rotation | 3 µl or 10 µl or 50 µl | 0.14 ml or 0.53 ml | 0.35 ml | 1.1 ml | 2 ml or 9.5 ml |

| max. dispensing speed* | 180 µl/min or 600 µl or 3000 µl | 8.5 ml/min or 32 ml/min | 21 ml/min | 66 ml/min | 120 ml/min or 570 ml/min |

| min. dispensing quantity | < 1 µl or 1 µl or 5 µl | 0.015 ml or 0.06 ml | 0.04 ml | 0.1 ml | 0.2 ml or 1 ml |

| Material viscosity | up to 1,000,000 mPa·s | up to 1,000,000 mPa·s | up to 1,000,000 mPa·s | up to 1,000,000 mPa·s | up to 1.,000,000 mPa·s |

| Dimensions** (lxwxh) | 190 x 89 x 341 mm | 182 x 89 x 353 mm | 195 x 96 x 424 mm | 200 x 96 x 452 mm | 200 x 96 x 471 mm |

| Weight aluminium*** | ca. 2.3 up to 2.9 kg | ca. 2.3 up to 2.95 kg | ca. 2.8 up to 3.5 kg | ca. 3.9 kg | ca. 4.3 kg |

| Weight stainless steel*** | ca. 2.5 up to 3.3 kg | ca. 2.6 up to 3.4 kg | ca. 3.7 up to 4.4 kg | ca. 5.1 kg | ca. 5.8 kg |

* 60 rotations/min

** without dispensing needle

*** incl. motor

Variant 2C: All 1C variants can be combined in different ways to form a 2C variant.

Potting material is transported from the material feeder to the dispenser.

Filling the material into the dispenser and dispensing through the rotor and stator.

Continuous bead application or spot

dispensing is possible.

(Starter) solution

Cost-effective and space-saving alternative for manual dispensing applications.

Individually combinable

Individual products can be combined or integrated into production lines.

Potting under atmosphere

Automated dispensing systems as standalone systems offer the ideal solution for series products.