dispensing systems and dosing systems for bonding, dosing and potting technology

In modern industrial production, dosing systems play a key role across all industries in terms of product quality, manufacturing efficiency and optimization of production processes. Dosing systems perform a wide variety of tasks such as bonding, insulating, thermal management, sealing and protecting components and ever-shrinking parts. Dispensing systems and dosing systems are used to introduce special and functionally prepared potting material mixtures such as epoxy resins, polyurethanes, silicones and thermally conductive pastes into the production process – in any desired viscosity, in abrasive and non-abrasive form.

overall more performant

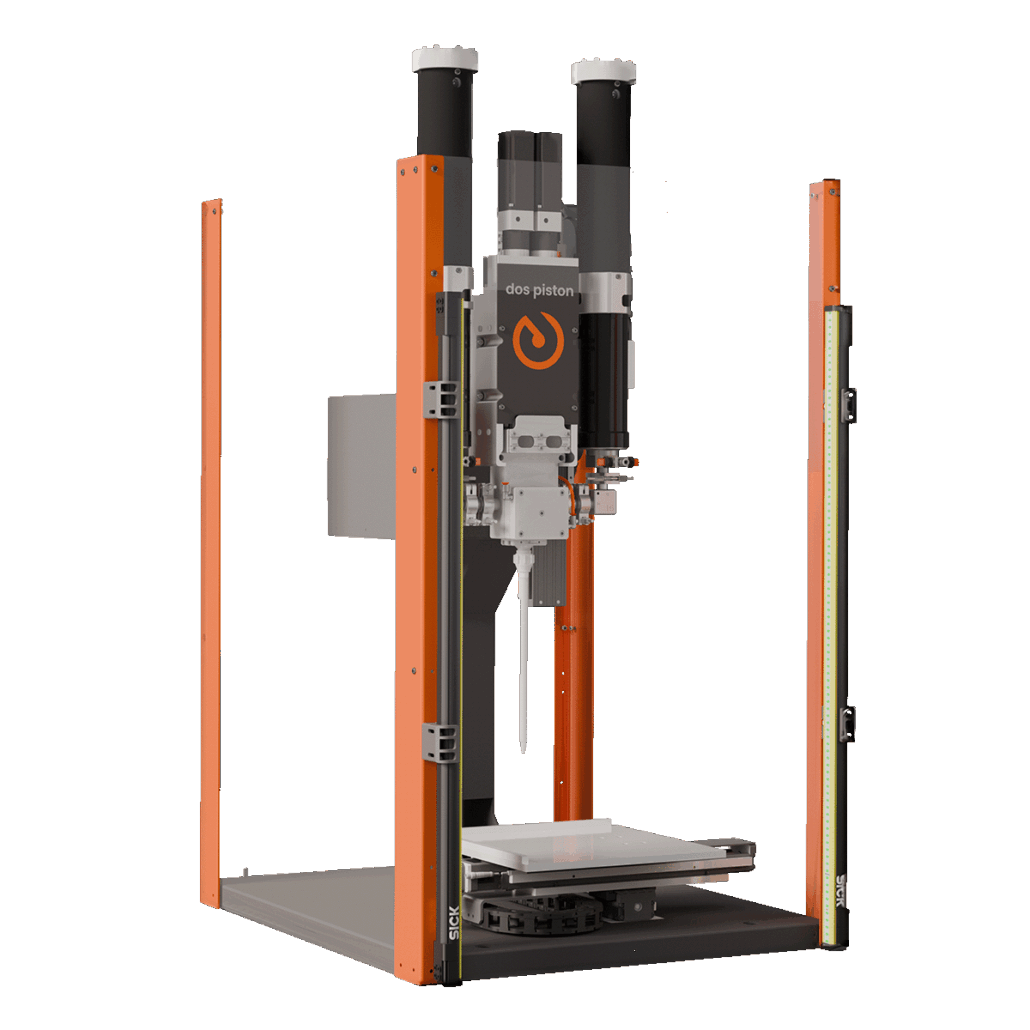

dos piston

dos prep

dos cell

dos in-line

example of a system

Material preparation and feeding with dos prep, together with the dos piston feeder and dos cell kinematics, form a functional unit for the automated dispensing of a wide variety of materials up to a viscosity of 70,000 mPa•s.

integrated products

- material preparation dos prep (2)for abrasive and non-abrasive materials up to 70,000 mPa•s

- standalone dos cell (3)axis system dos in-line (4) including protection cell for moving the dispenser in 3 degrees of freedom

example of a system

Together with the dos piston dispenser and the dos cell kinematics, the dos feed H material feeding system forms a functional unit for the automated dispensing of highly viscous abrasive and non-abrasive materials from the hobbock with a viscosity of 70,000 mPa•s and above.

integrated products

- material preparation dos feed H (2)for abrasive and non-abrasive materials from 70,000 mPa•s

- standalone dos cell (3)Axis system dos in-line (4) including protection cell for moving the dispenser in 3 degrees of freedom

dos piston

dos feed H

dos cell

dos in-line

questions and answers

What are the tasks of dispensing systems?

A: Dispensing systems are used to precisely and evenly apply liquids or sealants, such as epoxy resins and silicones, to components. This ensures accurate dispensing, optimizes the manufacturing process, and improves both product quality and efficiency.

When is a dispensing system needed?

A: Automated dispensing systems in potting technology provide numerous benefits for the production of electronic components. They allow precise and repeatable dispensing of various materials, making a significant contribution to improving the longevity, quality, and reliability of the components.

What are dispensing systems used?

A: Dispensing systems are used in numerous industries to apply liquids, sealants, or pastes precisely and evenly to components. In the electronics industry, they are used, for example, to dispense potting compounds onto circuit boards and sensors. In the medical technology field, they are employed in the production of blood glucose meters, where they precisely seal sensors to ensure their reliability and longevity.

When is a 1C dispensing system or a 2C dispensing system needed?

A: A 1C dispensing system is required when a single material, such as a resin or sealant, is used without mixing. It is ideal when only one product needs to be dispensed and applied, such as epoxy resins or silicones in the electronics industry or medical technology.

A 2C dispensing system is used when two components need to be mixed before being applied. This is often the case with materials like two-component adhesives or sealants, which develop their final properties only when mixed, such as epoxy resins or polyurethanes.

contact us

direct contact

sales(at)dosmatix.com

phone: +49 8783 9667 530